how do cement silos work

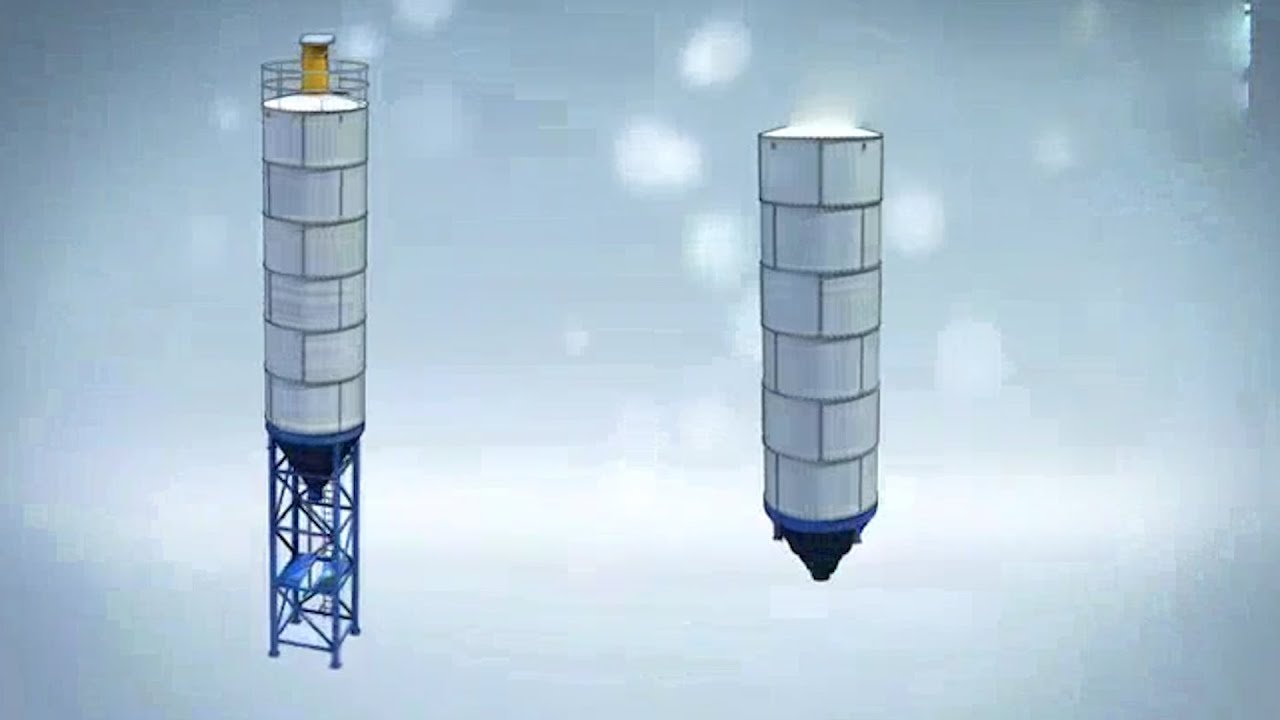

No matter which option you choose these silos will help make your concrete production faster and reduce your downtime. As a cement silo manufacturer with 15 years of experience FUREIN existing standard cement silo models are.

100 Ton Welded Type Cement Silos Silos Types Of Concrete Cement

1Surge bin after fixed by cement bulk cement trucks transport to the site and then the transfer line of bulk cement vehicle and cement warehouse cement tank into the feed pipe gas pressure with bulk cement vehicle will tank cement to the cement silo.

. In a concrete batching plant cement silos are used to store fly ash cement and other bulk materials required. Cement is a mandatory binding element in the production of concrete. According to different actual needs cement storage silo can be designed.

At the bottom of the silo there is an opening that connects to an augera device used to safely transport grain from one place to. The cement silo is an integral piece of equipment for any concrete production operation. The hoops are the primary structural stabilizer of the silo and for this reason.

While the silo is getting filled it automatically takes the necessary safety measures act. How do cement silos work Saturday March 19 2022 Edit. Its essential to inspect the condition of the.

Once your goods have been brought to the silo gravity will naturally control the flow at which the grain reaches the bottom of the silo. There is a charge for this service. CPI will carry out subsequent tests on request.

Concrete is much stronger in compression than tension so the silo is reinforced with steel hoops encircling the tower and compressing the staves into a tight ring. Save money by buying cement in bulk and storing it in a Cemen Tech cement silo. The cement silos come in fixed as well as movable form.

Correct connectIon of water suPPly electrIcal InsPectIon aanD testIng sILO sETuP The silo requires a 34 water supply with a minimum flow capacity of 900litres per hour at 2 BAR pressure. These silos consist of layers of concrete blocks that are layered together in circles and stacked on top of each other. The maximum cement silo capacity can reach 1000 T.

After the storage silo is fixed the bulk cement truck transports the cement to the construction site and then the bulk. The concrete staves act to distribute the load of the material over the hoops. During the process of transporting cement into the.

There are different types of of concrete silo construction methods depending on the type of silo you need. When the bulk concrete cement silo is working it must be erected by a special crane then placed on the pre-precast. Cement powder can easily absorb moisture from the air so cement silos must have good air tightness to ensure that they dry out over time.

Concrete stave silos are constructed from small precast concrete blocks with ridged grooves along each edge that lock them together into a high strength shell. Cement Silos Suppliers Aimix In Philippines Mix Concrete Dry Mix Concrete Concrete Some Easy Ways To Repair Cement Silos Storage Tank Concrete Silos Cement Silos Euromecc Cement Silo Of Concrete Batching Plant Concrete Silos Cement. Cement silo is a metal structure that stores all kinds of cast material.

Working principle of cement silo 1To install the cement silo it shall use a truck crane to lift it up and then it will be placed on the prefabricated concrete foundationCheck and ensure the silo is vertical and then the bottom of the cement silo must be welded firmly with the embedded parts of. The silo allows the product to be purchased and stored in bulk keeping costs to a minimum. These warehouses are also called silos.

Zimmerman Industries will help you evaluate your particular requirements to ensure that the cement silo best suited for you is selected. With the Use of Electricity at Work Regulations. Only this kind of a reservoir can protect the technical properties of cement from environmental impacts.

Cement production is a dusty process and requires highly efficient cement silos to be able to work in adverse conditions. How Does A Cement Silo Work. Slipform silos have been around for almost 100 yea.

The movable ones are termed as portable cement. The cement silo come very handy for construction sites and are used to hold and discharge cement and other powder materials such as PFA. Working principle of cement silo 1To install the cement silo it shall use a truck crane to lift it up and then it will be placed on the prefabricated concrete foundationCheck and ensure the silo is.

Cement silos are warehouses used for storage of cement and other cast materials like fly ash and mortar. Working Mechanism Of Cement Silos. A cement silo enables our customers to buy their cement powder in bulk store it and dispense when needed.

Choose from low profile or upright and from gas diesel or electric models to store your cement. The silo control system controls the filling process of the silo. Cement storage silos are on-site storage containers that used for the storage and distribution of various types of cement mixtures.

A cement silo is a type of vertical tank that is used to store various bulk materials for example fly ash grain and cement. Spiral steel silos for cement storage come in a variety of sizes which makes them ideal for both large-scale and small-scale cement plants. The vertical tank is fitted with a clear material level system which shows the position of the contents.

30T 50T 60T 80 T 100 T 120 T 150 T 160 T 180 T 200 T 250 T 300 T. Cement is one of the binding materials used in the production of concrete a vital. Cement is stored for the operation of the concrete factory.

In a concrete dosing plant a cement silo is used to store cement powder which is needed for the production of concrete on the fly. They are spiral conveyors that come in different sizes and models depending on the demand and size of the concrete batching plants. Jun 11 2018 Keywords.

Cement silocement silo working principle The working principle of cement silo is as follows. How do cement silos work. Cement silos above 300T need to be customized in advance.

Concrete stave silos are reinforced with exterior galvanized steel hoops which help compress the walls and provide necessary tension for structural integrity. Since grain from the upper layers exert a great deal of pressure additional thinner layers are needed at the bottom of the silo.

Installation Of Two Sets Of Cement Silos For Concrete Batch Plant Pakistan Ready Mixed Concrete Concrete Mix Concrete

Http Www Chinaconcretebatchingplant Com Cement Silos Cement Silo 12 Html Concrete Mixing Station Equipment According To Concrete Manufacturing Storage Tanks

Cement Silo Cement Silos Machinery For Sale

Iowa Concrete Silos Old Barns Silos Bank Barn

Working Video Of Aimix Cement Silo Silos Types Of Concrete Cement

Cement Silo Cement Storage Silo Manufacturer Industry Silo Silos Cement Industrial

Cement Silo Series Eurosilo Collapsible Design D 6 2 M From 305 To 605 T Cement Silo Series Eurosilo Modu Construcoes Metalicas Estrutura Metalica Metal

Concrete Silos Vs Steel Silos Del Zotto Concrete Products Of Fl

Cement Silo Professional Cement Silo Manufacturer For Sale Types Of Concrete Plant Sale Silos

Cement Silo With 50t 100t 150t 200t 300t 400t 600t 800t For Your Different Use Contact Me If You Are In Need Email Jsco Cement Silos Machinery For Sale

50 Ton Horizontal Cement Silo Was Going To Malaysia Cement Silos Malaysia

Cement Silo Of Concrete Batching Plant Concrete Silos Cement

How Does A Concrete Cement Silo Work Knowledge Jinjiang Unik Machinery Ltd

Cement Storage Silos Silos Cement Painting Cement

Instructions To Construct Your Cement Silo For Onsite Storage Youtube

Large Cement Silo High Quality Sealing Cement Silo For Sale Silos Types Of Concrete Cement